HCM Artificial Stone Vertical Shaft Mixer

HCM 250/375/500/750/1000/1250/1500/2000

Category:

key word:

Product details

- product description

- Structure

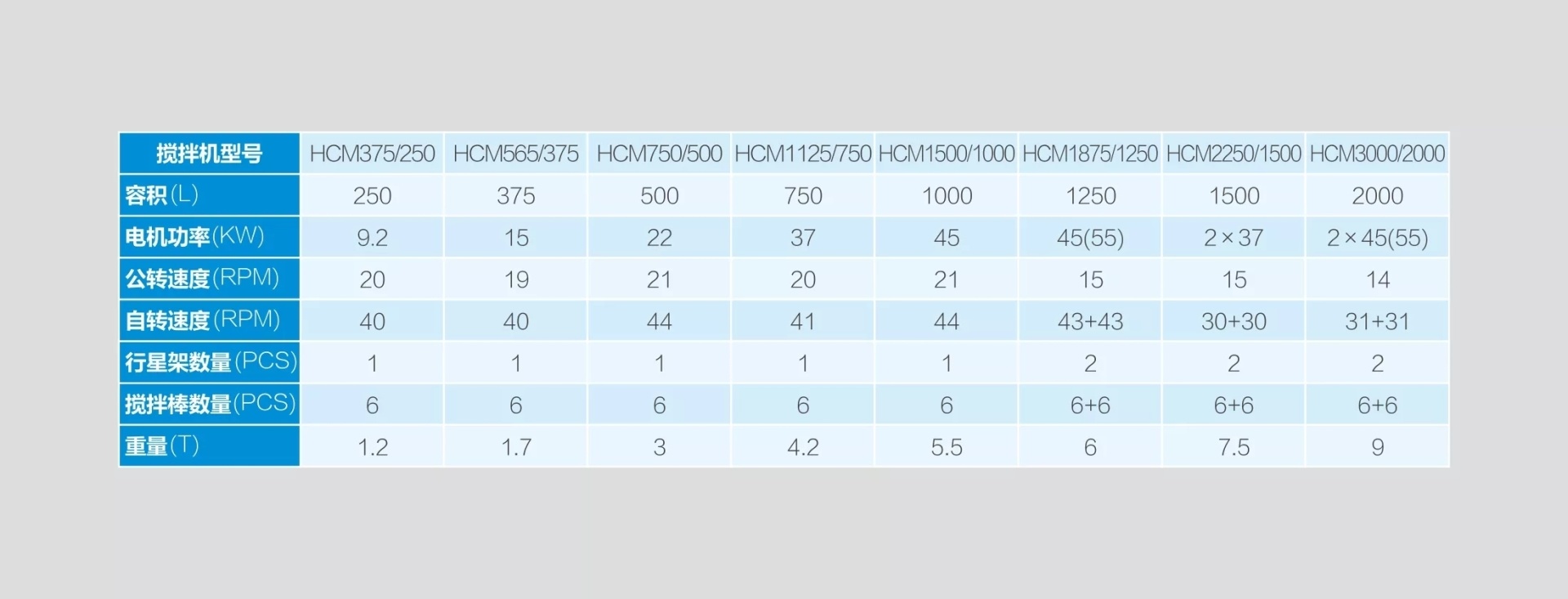

- Parameter

- Case

-

- Commodity name: HCM Artificial Stone Vertical Shaft Mixer

HCM 250/375/500/750/1000/1250/1500/2000

HCM 250/375/500/750/1000/1250/1500/2000

In the field of artificial stone manufacturing, the quality of mixing equipment directly determines the performance, appearance and production efficiency of the final products. The HCM Artificial Stone Vertical Shaft Mixer stands out as a professional and efficient solution tailored for the unique mixing needs of artificial stone production, winning wide recognition from manufacturers with its excellent performance and reliable stability.

The most prominent advantage of the HCM Artificial Stone Vertical Shaft Mixer lies in its outstanding mixing uniformity. Artificial stone production requires precise blending of various raw materials such as resin, stone powder, pigments and additives. The mixer adopts an advanced vertical shaft structure and a specially designed mixing blade system. The vertical shaft drives the blades to rotate at a reasonable speed, creating a strong turbulent flow inside the mixing chamber. This turbulent flow ensures that each raw material particle can fully contact and blend with others, avoiding the problem of uneven mixing that often occurs in traditional mixers. Whether it is fine stone powder or viscous resin, the mixer can achieve consistent mixing results, which lays a solid foundation for the stable color and strength of artificial stone products.

Another key feature of the HCM Artificial Stone Vertical Shaft Mixer is its high production efficiency. In the context of large-scale artificial stone production, efficiency is crucial for reducing costs and meeting market demand. The mixer is equipped with a powerful drive system that provides sufficient power to handle large batches of raw materials. Its optimized mixing chamber volume can accommodate more materials in a single mixing cycle, while the scientific mixing process shortens the mixing time without compromising mixing quality. Compared with conventional mixers, the HCM Artificial Stone Vertical Shaft Mixer can increase the daily production capacity of artificial stone manufacturers by 20% to 30%, effectively improving the overall production efficiency of the workshop.

Durability is also a highlight that cannot be ignored for the HCM Artificial Stone Vertical Shaft Mixer. The raw materials used in artificial stone production, especially stone powder, have strong abrasiveness, which puts high demands on the wear resistance of mixer components. The mixing chamber and blades of this mixer are made of high-strength wear-resistant alloy materials, which have excellent resistance to friction and impact. After long-term use, the components still maintain good performance, reducing the frequency of maintenance and replacement. This not only lowers the operating cost of manufacturers but also ensures the continuous and stable operation of the production line. -

Related products

Online inquiry

Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible