Product details

- product description

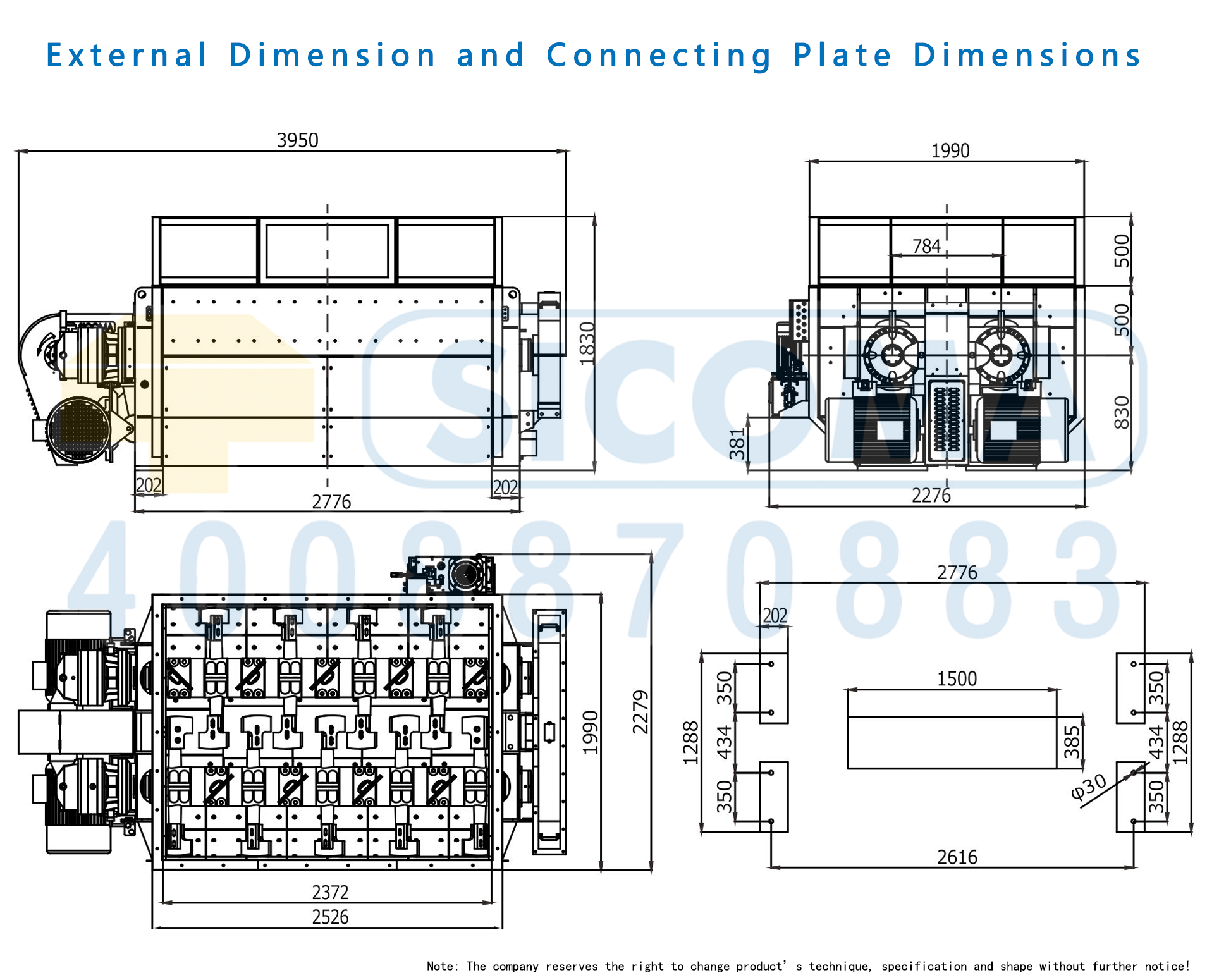

- Structure

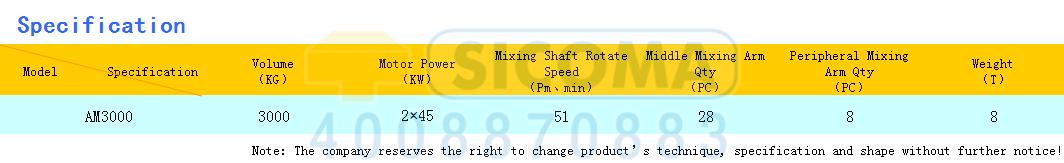

- Parameter

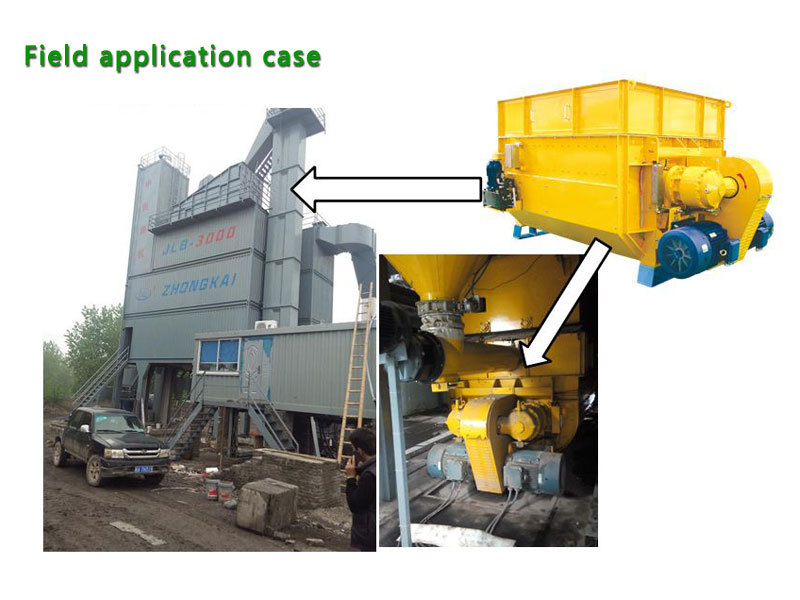

- Case

-

- Commodity name: AM Asphalt Mixer

AM 3000

AM 3000

◆ Innovative tank design without dead area for well-distributed mixing

◆ Energy saving and environmental-friendly, improved mixing efficiency with hot oil heat reservation and warm-up functions at the tank bottom

◆ More stable transmission and higher working efficiency with unique single-shaft structure

◆ Strong overload resistance, lower noise and reliable operation with coaxial gear design at the tail end.

◆ Faster discharging and better sealing with large size discharge door design

◆ Shorter mixing time and better mixing quality with two-way mixing arms

◆ Outstanding wear resistance with alloyed mixing blades

◆ Easy maintenance, Superior performance-price ratio

The tank design of AM Asphalt Mixer is one of its highlights. It has an innovative tank design without dead area which enables well-distributed mixing. This unique design ensures that every part of the asphalt mixture in the tank can be evenly mixed contributing to high-quality end products.

Energy saving and environmental-friendly are important aspects of this AM Asphalt Mixer. With the hot oil heat reservation and warm-up functions at the tank bottom it can improve the mixing efficiency. It not only saves energy but also reduces environmental impact which is in line with the modern concept of sustainable development.

The single-shaft structure is also a key feature. This unique single-shaft structure makes the transmission more stable and enhances the working efficiency. It allows the mixer to operate smoothly during the mixing process and complete the mixing tasks in a more efficient way.

The coaxial gear design at the tail end is another advantage. It gives the mixer strong overload resistance which means it can handle higher loads without being easily damaged. At the same time it also reduces noise during operation and ensures reliable operation.

The large-size discharge door design is beneficial for faster discharging and better sealing. This design allows the asphalt mixture to be discharged quickly and at the same time prevents leakage effectively which is very important for the overall operation efficiency and quality control.

The two-way mixing arms contribute to shorter mixing time and better mixing quality. They can stir the asphalt mixture from different directions making the mixing process more thorough and reducing the time required for mixing.

Finally the alloyed mixing blades have outstanding wear resistance. This means that they can last longer and maintain good performance even after long-term use reducing the need for frequent replacement and maintenance costs.

-

-

-

Related products

Online inquiry

Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible