Understanding Asphalt Mixers: Key Insights and Applications

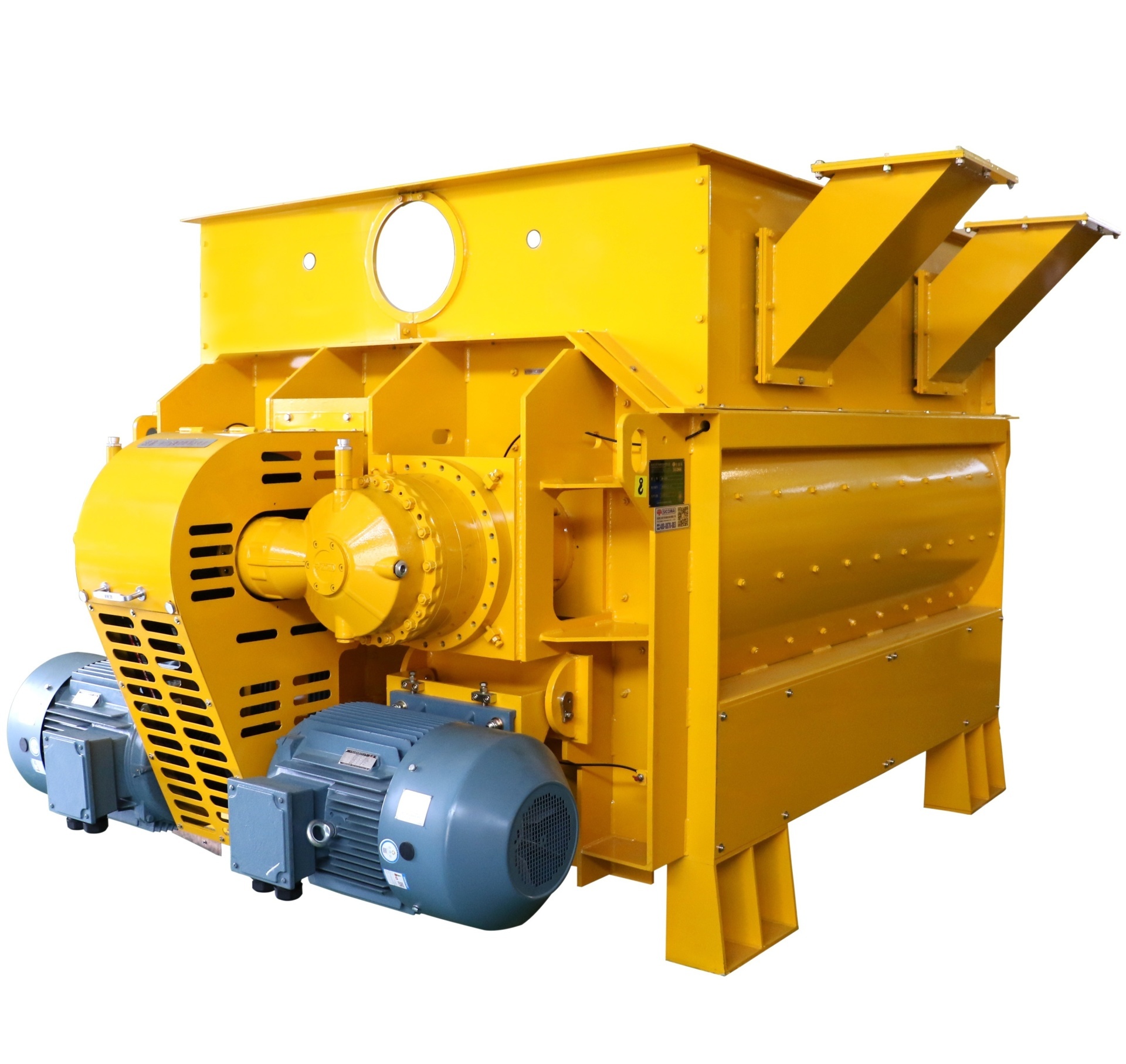

Asphalt mixers are specialized machines designed to combine various materials to produce asphalt, which is a vital component in road construction and maintenance.

Asphalt mixers are specialized machines designed to combine various materials to produce asphalt, which is a vital component in road construction and maintenance. The primary role of an asphalt mixer is to blend aggregates, asphalt binder, and additives to create a uniform and durable mixture. This process ensures that the asphalt possesses the necessary properties for effective road surface performance, such as durability, flexibility, and resistance to weathering.

There are several types of asphalt mixers, each suited for different production scales and requirements. Batch mixers are one of the most common types, where the mixing process occurs in distinct batches. These mixers allow for precise control over the mixing process, making them ideal for producing small quantities of customized asphalt mixtures. On the other hand, continuous mixers operate non-stop, providing a steady flow of asphalt. They are typically used in large-scale operations where high production rates are necessary.

The mixing technology employed in asphalt mixers can significantly influence the quality of the final product. Modern asphalt mixers often incorporate advanced features, such as precise temperature control, automated mixing processes, and sophisticated control systems. These innovations not only enhance the mixing efficiency but also ensure that the final asphalt mixture meets stringent industry standards.

In terms of applications, asphalt mixers are primarily used in road construction, where asphalt is applied as a surface material for highways, streets, and parking lots. The quality of the asphalt produced directly impacts the longevity and safety of the roads. Additionally, asphalt mixers are also utilized in various maintenance projects, including pothole repairs and resurfacing existing roads.

In summary, asphalt mixers play a pivotal role in the construction and maintenance of road surfaces. With different types available for various production needs, these machines ensure that high-quality asphalt mixtures can be produced efficiently. Understanding the capabilities and applications of asphalt mixers can help professionals in the manufacturing and construction sectors make informed decisions about their machinery needs, ultimately contributing to more durable and reliable road infrastructures.

RELATED BLOG

Enhancing Construction Efficiency with Quality High Performance Concrete Mixers

In the manufacturing and processing machinery industry, specifically in the field of engineering and construction machinery, concrete mixers play a crucial role in the production of high-quality concr

Top 10 Best High Performance Concrete Mixers for Construction Projects

Discover the top-performing concrete mixers for your construction projects. From portable options to heavy-duty models, find the perfect mixer for your needs.

Unlocking the Secrets of High Performance Concrete Mixers

Discover the key factors that make a concrete mixer the best in terms of high performance. Dive into the world of manufacturing and processing machinery, specifically focusing on engineering and const

Maximizing Efficiency with Aerated Concrete Mixers: A Comprehensive Overview

Aerated Concrete Mixers are specialized equipment designed to create aerated concrete, a lightweight construction material known for its excellent insulating properties and strength. These mixers are essential in the manufacturing and processing machinery industry, particularly for applications involving concrete products. The core function of an aerated concrete mixer is to effectively blend raw

How Butterfly Valves Enhance Manufacturing Process Efficiency

How Butterfly Valves Enhance Manufacturing Process Efficiency Table of Contents 1. Introduction to Butterfly Valves in Manufacturing 2. Understanding Butterfly Valves and Their Mechanism 3. Key Benefits of Using Butterfly Valves in Manufacturing 4. Applications of Butterfly Valves Across Industries 5. How Butterfly Valves Improve Operational Efficiency 6. Cost Reduction St

Understanding Small Concrete Mixer Machines: Essential Insights for Professionals

Small concrete mixer machines have emerged as indispensable tools in various construction and manufacturing processes. These machines are designed to efficiently produce small batches of concrete, making them ideal for both residential and commercial projects. Understanding the features, benefits, and applications of small concrete mixer machines can help professionals make informed decisions when